Manufacturing of injection molds

- Main page

- Our company's offer

- Manufacturing of injection molds

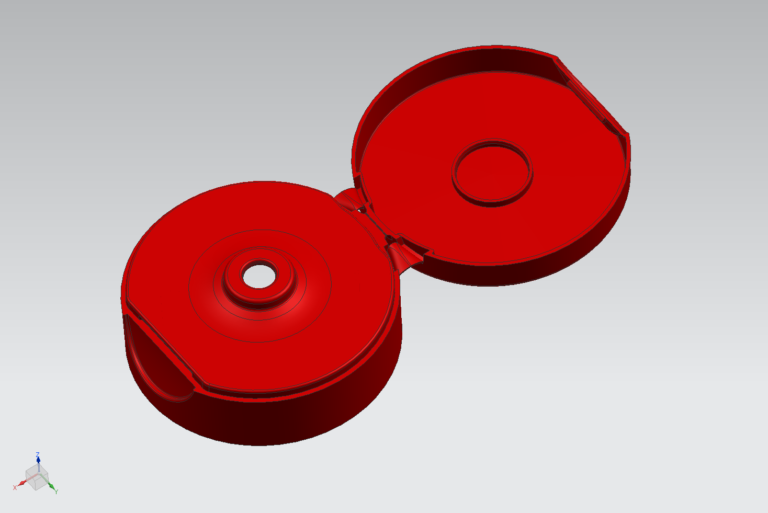

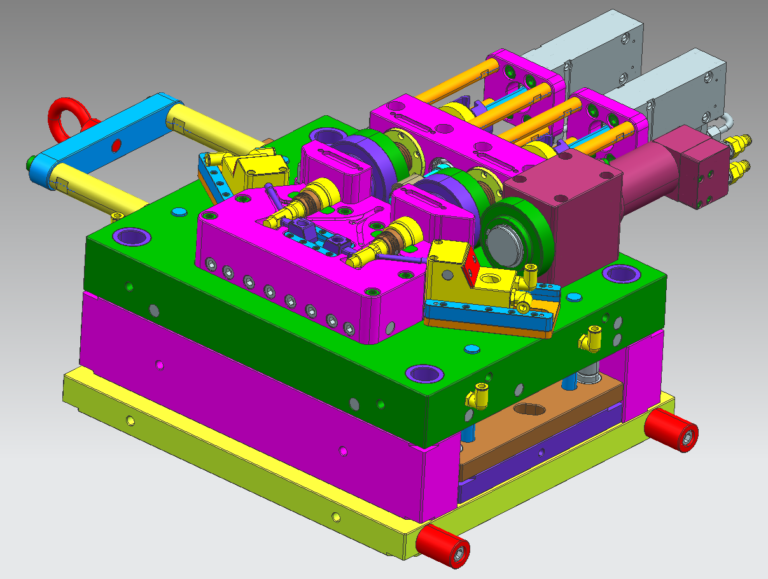

Since 1979 , we have been manufacturing injection moulding instruments for plastics processing. Thanks to our qualified staff of designers, technologists and operators, we take on technological challenges and very difficult applications, and our extensive machine park allows us to make highly specialized instruments that will meet the greatest expectations of our contractors.

We offer a comprehensive service starting from the design of the detail (on the customer’s order we can design the shape and form of the finished product along with solving all the construction problems), through the preparation of the documentation and the injection mold, to the test injections taking place with the participation of the customer at our injection molding plant located at the company’s headquarters.

We make injection molds with maximum dimensions of 1500 x 800 x 1000 mm. We are able to make multi-slide molds with compiled parting lines with drives: mechanical, hydraulic, pneumatic, electric. We can make molds with screw cores for thread forming or with mortises. We have developed from scratch a solution for expansion mandrels used in sewer fittings.

We only use materials from trusted and recognized suppliers such as:

and many others…

All operations are performed using programs and machines from brands such as:

Our machinery allows us to complete all operations in-company. We have the ability to provide operations:

CNC milling

CNC lathing

Electrical discharge machining

Wire cutting

Flat grinding

Circular grinding

Microwelding

We have a high-tech locksmith shop, whose specialized crew takes care of the assembly and ongoing servicing of the instruments in our company.

We have our own quality department, which is equipped with a coordinate measuring machine, microscope, hardness measuring machine, etc., so that each molded part is verified before it goes to assembly, and in addition we have the ability to make sure that the molded part, which was created in our company, complies with the drawing tolerances.